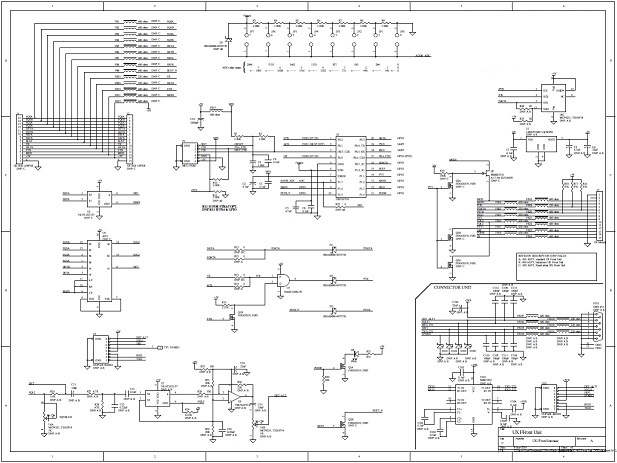

| The UX FFront Unit is an alternate design-spin on the original UX Front Unit used by the ICOM IC-900 UX band modules. It acts as a form-fit-function replacement for the orignal PCB Assembly (PCBA), in the case where the original board is lost or damaged beyond repair. However, with alternate software and assembly components, the module can perform some interesting tasks. One of which is to act as an interposer, whereby the module presents to the IC900/901 as one band, but the on-board microcontroller (MCU) translates the base-controller's frequency commands to the module's frequency space. Ostensibly, This would allow a module of one type to connect to a transverter, and seamlessly appear to operate on the antenna frequency of the transverter. Thus, one might then be able to populate their IC-900/901 with a rare frequency band (such as is offered by the UX-19 10m, or UX-129 1200 MHz modules) by using a more readily available module (such as the UX-29 2m module) and a transverter. Another option allows the module to act as a stand-alone transceiver that provides line-level, squelch-gated audio to a user connector. A simple RS-232 serial interface allows for remote control, or the radio can simply operate on a fixed frequency. A duplex receiver is one of the primary use-cases for this option. A small MCU is used to capture digital information from the base-controller and perform many of the tasks that were dedicated to discrete logic I.C.s on the original Front Unit design. This, along with some other design features, greatly reduces the parts count of the basic PCBA. The software for this basic function PCBA (designated as a RevA assembly) is fairly simple and is focused on acquiring the 10-bit header frame and pulsing the PLL strobe signal after the 20-bit PLL data frame. The original 4066 switch array was replaced by 4053 (3P2T) and 74LVC1G3157 (1P2T) IC switches to create a 4P2T analog switch array (which occupies less space than two 4066 I.C.s) to handle the main/sub band selection. Using the MCU to capture the header frame allowed a number of components to be elliminated from the design. To save pins, the ADC on the MCU is used in concert with a 7-resistor divider to achieve an 8-position device address selection mechanism (only 6 of these positions are used to support the radio modules). For the "Interposer" option, designated as a RevB assembly, only a few 0-ohm resistors need be moved to allow the MCU to solely control the data, clock, and strobe signals feeding the band-module PLL chip. The software for this option is somewhat more complex as the MCU now must capture the PLL data as well, and then process the data to calculate the actual PLL data frame which is then sent to the band-module PLL chip. The original "Stand-alone RX" option has been deprecated in favor of a T/R version, designated as a RevT assembly, there are a number of component changes needed (and jumper wires for the first run PCBs). Several parts are elliminated, And more are added to allow the RevT to control the band-module PLL and provide de-emphisized (or, optionally, "flat") DET audio and accept "flat" MOD audio via an 8-pin, 1.5mm connector installed at J1. The removed parts are those that would be used to connect to a base-controller such as that provided my the IC-900 or IC-901. The de-emphasis and squelch circuits are borrowed from the ACC FC-900 and are very basic. A digital POT provides squelch and level control which can be fixed, or adjusted using simple serial commands issued over an RS-232 interface. An out-board adapter is planned to provide a means of adusting these settings in the field. This adapter can be installed in the band-module front cover (a DSUB-9 opening must be cut), or a 3D-printed replacement cover. A companion application for use with WIN10 PCs is available which simplifies the configuration of the RevT version. At some point, this application will be modified or cloned to support the RevB version (the RevA version does not require configuration). See the github repo at https://github.com/ke0ff/UXFFconfigurator. The Software link below provides instructions to obtain the source code for the various versions of this project. Links to the tools needed to compile and program the SiLabs C8051F530 microcontroller used for this project are provided below. |

|

Quick-Links:

Detailed hardware design Detailed software design Design Links |

The

The